| Navigation - Scheduling Module Icon | ||

|

||

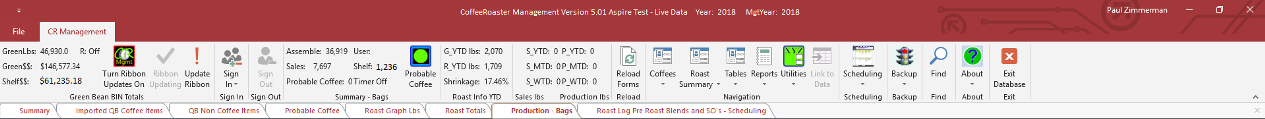

| Scheduling - Scheduling Module | ||

| |

Opens the Scheduling Calendars.

Scheduling Calendars include the major workstations including: 1) Roasters Calendar 2) Flavoring Calendar 3) Grinding Calendar 4) Packaging Calendar As the Calendars are opening you will be prompted on whether you want to close some of the existing forms to reduce resources, it is recommended that you select 'Yes' and have CoffeeRoaster close the unnecessary forms. |

|

| |

Opens the

Production Scheduling Form. To use the Production Scheduling Form

to add Roasts/Coffees to the Scheduling Calendars you need to make the

following selections/entries. 1) Select the appropriate Roast Date. You can schedule Roasts for future days if you choose to. 2) Select the Roast that the Produced Coffee is derived from using the Select Roasts Group and then select a Roast from the List Box. The Select Group choices are: a) CR Assemble Only b) Orders Only c) Show All 3) Select the bagged Coffee that will be scheduled for production from the List Box. If the Coffee that you want to schedule for production is not shown in the List Box change the selection in the Select Which Coffees to Display Group to Show All. 4) Once a Roast and specific bagged Coffee are selected enter a Route from the Select Route drop down menu. The Routes shown should be properly configured for each coffee specifying which Roaster the Roast is to be performed on, which Flavoring workstation is involved if necessary, which Gringing workstation is to be used and finally which Packaging Workstation the Coffee should be routed to. 5) Enter the Green Lbs value in Lbs for the Roast in the Green Lbs field (yellow background). Once the Green Lbs have been entered, CoffeeRoaster calculates the estimated yield and Estimated Units for Packaging. 6) Review the Repeat drop down menu box. By default a Roast is scheduled for 1 cycle, but you can enter a larger number to Repeat the Roast multiple times. 7) Once all the necessary fields are filled out, click on the 'Add to Pending' button. At this point in time CoffeeRoaster performs a check for materials and formulas including verfiying that sufficient Green Beans are available and that Roast formula components total 100%. If these checks pass, the Roasts are added to the 'Pending for Scheduling' List Box. 8) To Schedule the Roasts\Coffees in the 'Pending for Scheduling' List Box click on the Schedule button. The Roasts/Coffees will be scheduled on the appropriate Workstation calendars. Each Workstation has a printable report that indicates which roasts/coffees are to be processed for the selected date. When the Schedule button is clicked the appropriate deductions are made for the Green Bean BINS. This means that the Green Beans BIN totals for Single Origins will indicate what is still available for Roasting/Scheduling, not what is actually in the Green Bean BINS due to Scheduled Roasts that have not been completed. |

|

|

|

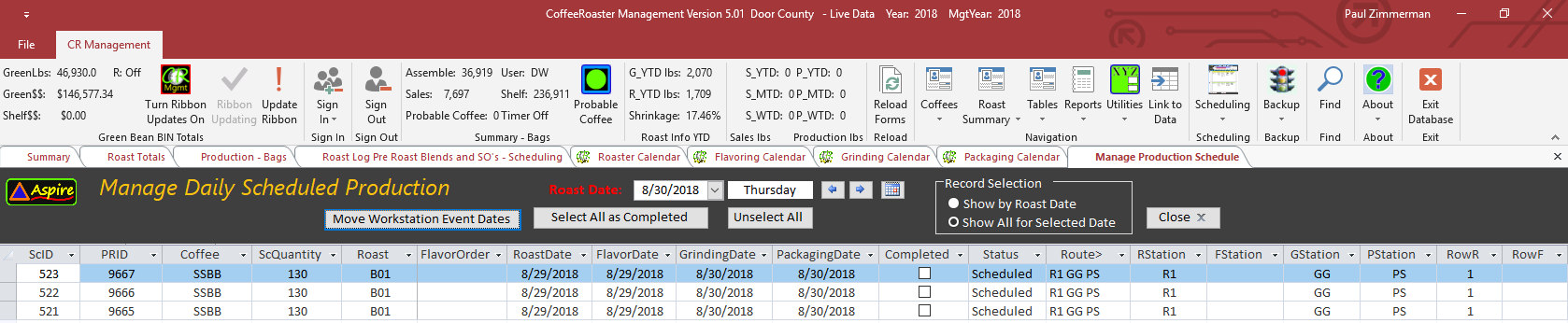

The Manage Daily Production Results form lists each Roast scheduled by the Scheduling Module. Each row has a completed field to be checked confirming whether production proceeded as scheduled. If specific Production Tasks were not successfully completed you can use the 'Move Workstation Event Dates' to adjust individual workstation dates. If all scheduled production tasks were successful you can click on the 'Select All as Completed' button, otherwise you will need to individually click on the tasks that have been completed as shown in the form below. | |

|

||

|

|

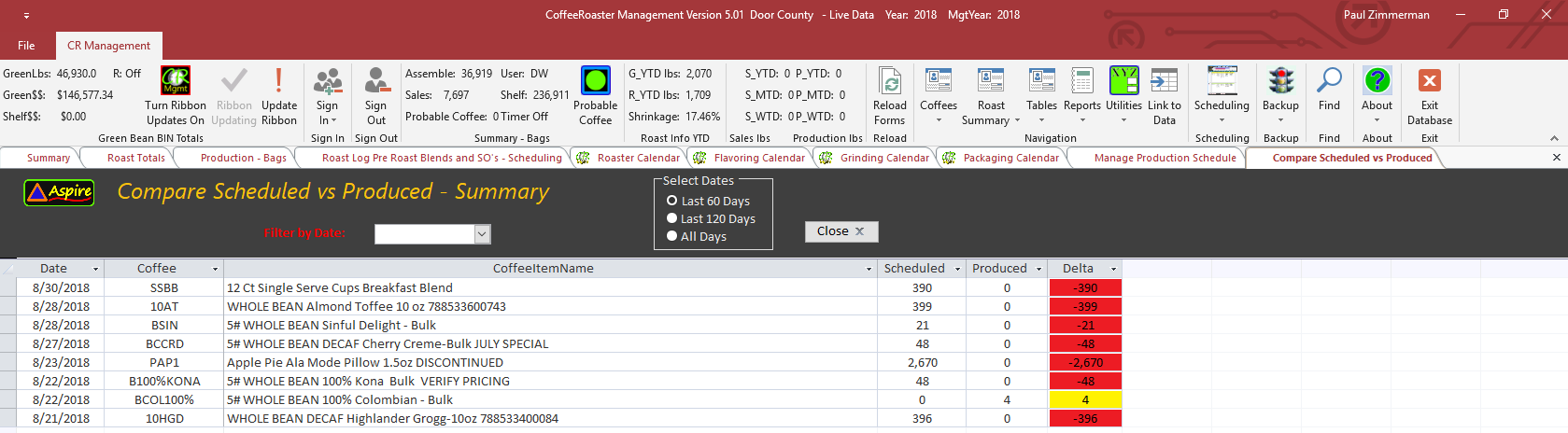

The 'Compare Scheduled vs Produced' form provides a means of comparing Scheduled Production of Coffees vs Produced Coffees over a time period of 60 or 120 days. In the form below we have Scheduled Coffees without Produced quantities indicating a potential problem or that the items have been scheduled and are still in the Production process. | |

|

||

|

|

||

|

|

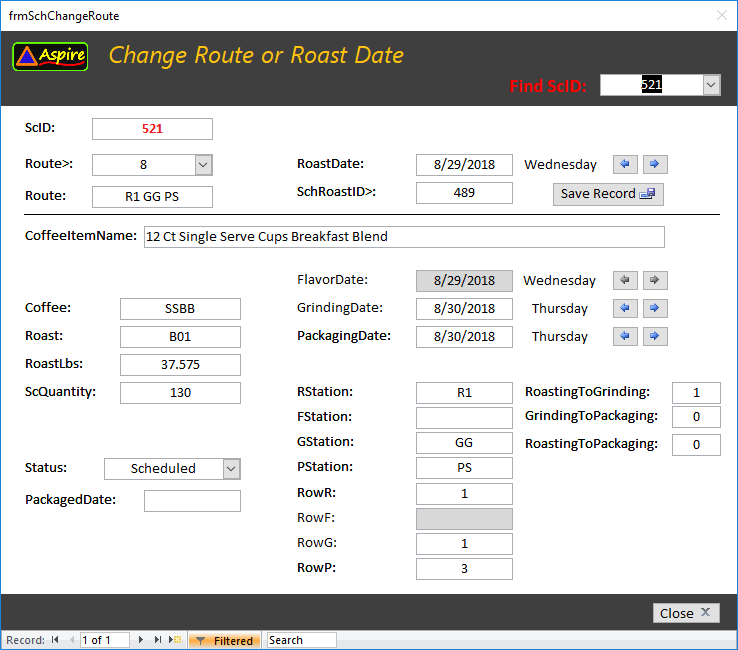

This option provides the ability

to change the dates that Scheduled Coffees are set to proceed through

the Roasting, Flavoring, Grinding and Packaging. For each

scheduled Coffee Item the Scheduling Module produces a unique numeric

value called ScID. Select the scheduled item that you want to change

from the Find ScID drop down menu in the top right of the form.

Then, confirm or change the Roast Date, Flavor Date if necessary,

Grinding if necessary and Packaging. This tool can be particularly

useful in the event of Workstation breakdown and you need to change

production dates. |

|

|

||

|

|

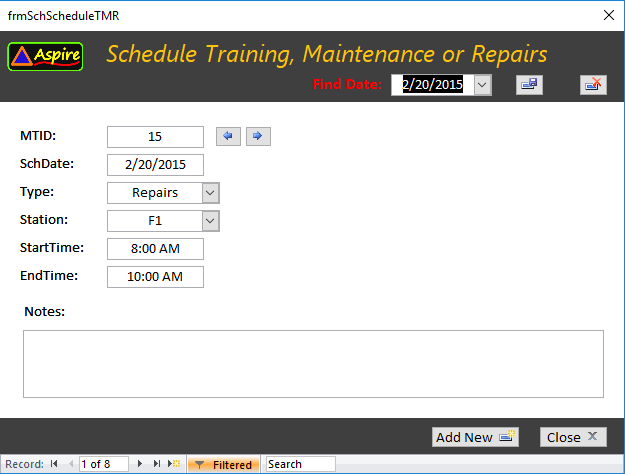

The Schedule Training, Maintenance or Repairs form gives you the ability

to add these events to the Calendar. Training, Maintenance and

Repair events display at the top of the box for each daily Calendar

Workstation before the Coffee related activities are displayed. To

enter a Training, Maintenance or Repair event open this form and enter

the required information in the fields. Some fields are drop down

menus. Optionally, you can enter a note if required. |

|

|

||

|

|

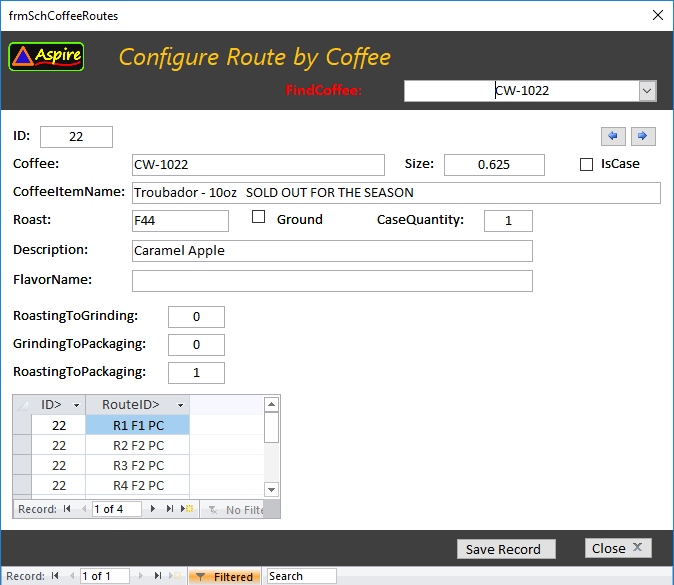

The Routes Configuration Form is used to configure the different routes

or paths that Green Beans go through to become finished Coffee. In

a large production facility with multiple Roasters, Flavoring stations,

Grinders and Packaging a Coffee will generally have several Route

possibilities. Routes are preconfigured by Aspire prior to

software delivery, if a change in equipment requires additional routes

contact Aspire. Many of the Coffee fields below are read/only,

this data is configured individually for each Coffee in the Coffee

Configuration forms. To select which routes apply to a given

Coffee, use the drop down menu for the RouteID> to add Routes. You

can add as many routes as apply to the Coffee. Routes use the following format: RxFxGxPx 1) Rx - the x is a numeric or alphabet character value assigned to different Roasters 2) Fx - the x is a numeric or alphabet character value assigned to different Flavoring workstations 3) Gx - the x is a numeric or alphabet character value assigned to different Grinding workstations 4) Px - the x is a numeric or alphabet character assigned to different Packaging workstations  |

|

|

||

|

|

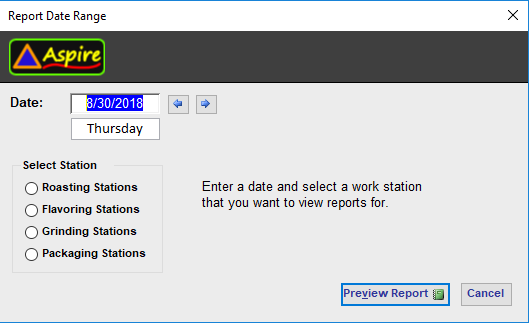

The Scheduling Reports form allows you to select a date to print Coffee

Workstation daily tasks. Select a date and then a Workstation to

preview and optionally print Workstation Reports. |

|

| Holidays and Production Dates | ||

|

|

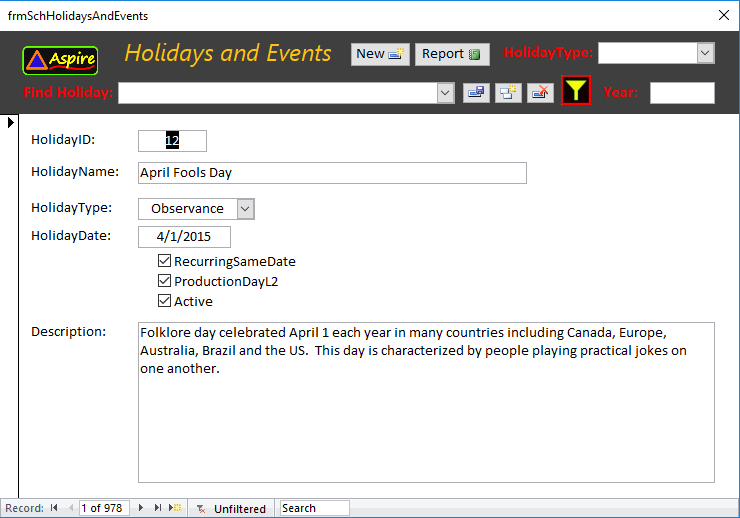

The Edit Holidays and Events

form, shown below, provides the ability to manage Holidays and Events.

You can add a new custom event, modify an existing Holiday/Event or

review the Event Description. |

|

|

|

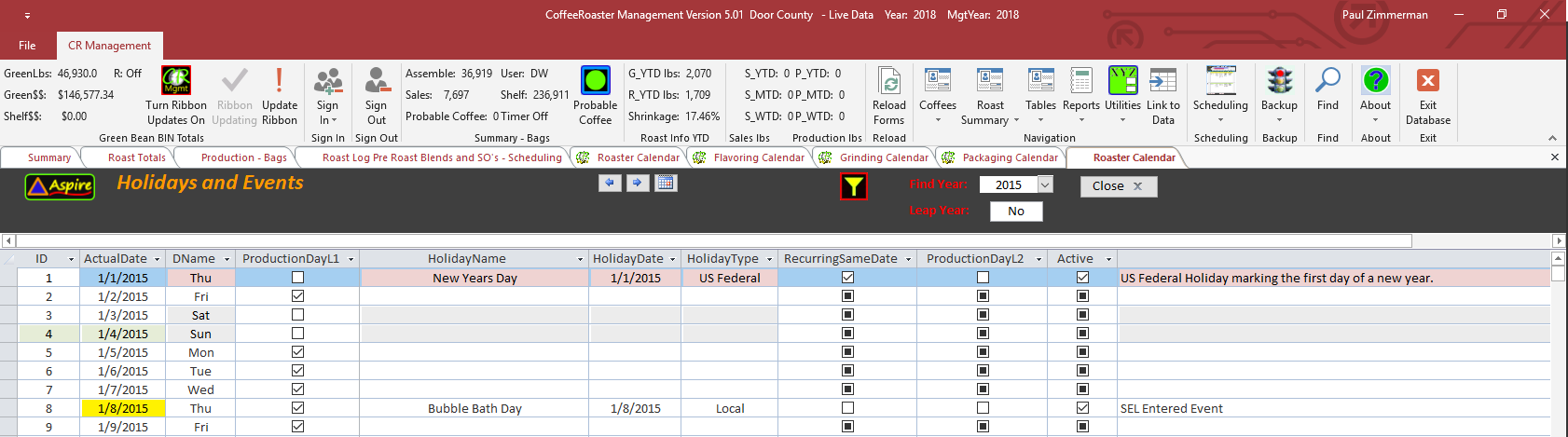

The Holidays and Events form (shown below) manages the events and holidays that are displayed at the bottom of the Scheduling Calendars, but also manages which days are scheduled as Coffee Production days. By default, major Holidays and Weekends are scheduled to be non production days. It is important that at the beginning of each year that you review what days are selected as Production Days and which Days are not. You can add custom Holidays and Events and also define them as Production Days or not. | |

|

||

|

||

|

|

Opens up the Roast Log form for Post Roast Blends and Single Origins Roasted as blend components. | |

|

|

Opens up the Roast Log Form for Pre Roast Blends and Single Origins packaged as Single Orign coffees. | |

|

|

||