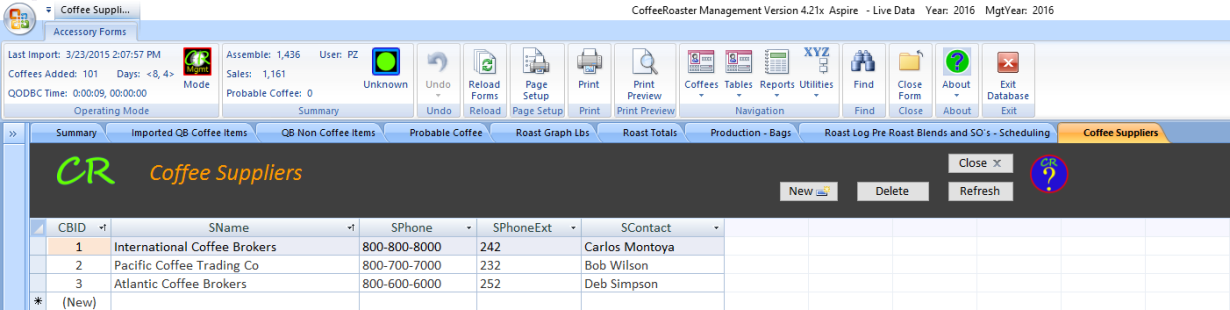

The Supplier Form has fields to enter the Supplier Name (SName), Phone, Extension and Contact, only the SName field is required. Add a row to represent each Coffee Supplier, when you are done close the form and these suppliers will be available in drop down menus in higher level forms.

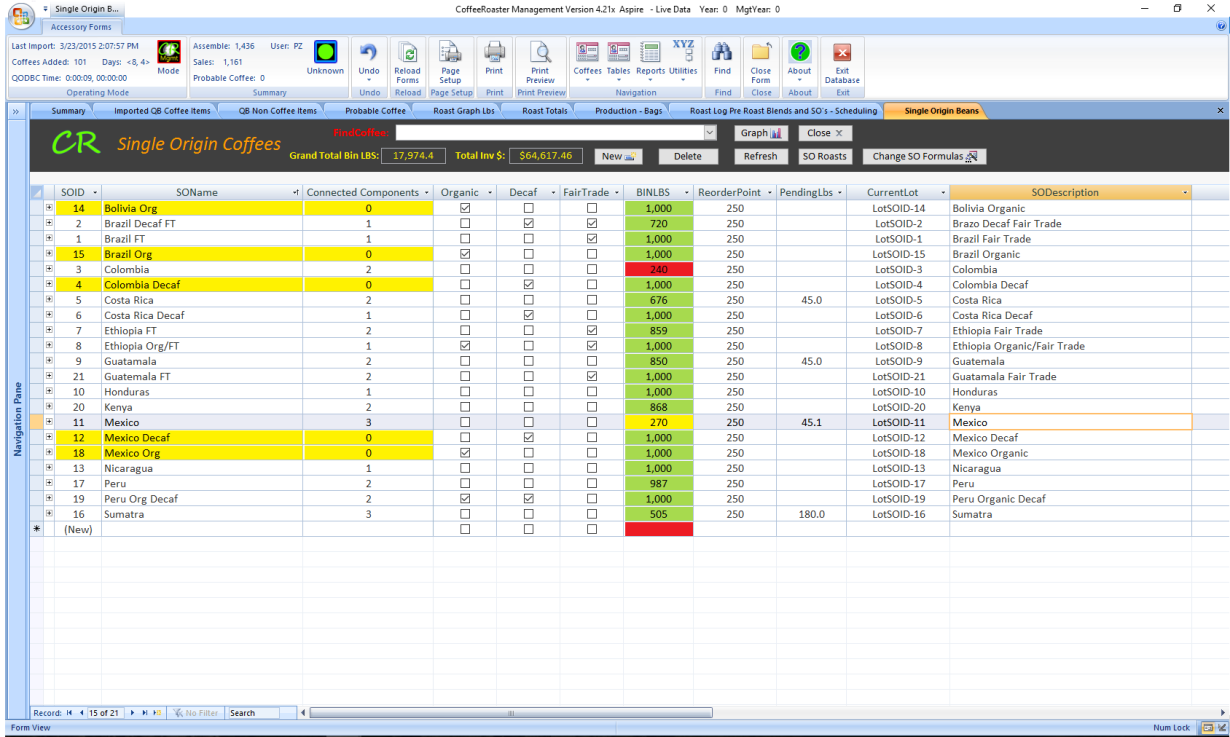

The next item to be configured is your Single Origin BINS. The Single Origin BINS Form will have a row representing each of your Single Origin Coffees with fields for Single Origin Name (SOName), current inventory (BINLBS), ReorderPoint (optional), Single Origin attributes (Organic, Decaf, Fair Trade), CurrentLot and Description (SODescription). Enter a new row for each of your Single Origins, try to keep the SOName as short and to the point as possible, duplicates are not allowed on the SOName field. As you enter a new Single Origin, CoffeeRoaster will create a new, unique SOID value that represents the row. The Connected Components field is a calculated field and does not need to be managed.

Each Single Origin coffee that is received by your business may come with specific Single Origin attributes. CoffeeRoaster software allows you to configure these attributes for each Single Origin including Organic, Decaf and Fair Trade. These attributes are similar to Final Roast attributes of Organic, Decaf and Fair Trade, but there is an important difference. Final Roast attributes are configured on how a Final Roast (bagged product) is marketed. If a Final Roast attribute is Decaf, then the Roast formula should come from Single Origin coffees which also have the Decaf attributes. For Final Roasts marketed as Organic, the final product must be composed from Single Origins that match the necessary legal definition for Organic that is needed for your certification. The Single Origin attributes shown in the form below represent the attribute of the Single Origin, not the attribute of the Final Roast.

The BINLBS field is important, this field represents your current inventory for that Single Origin in LBS. You can edit this field manually after a physical inventory, if CoffeeRoaster is configured properly with Roast Components and Final Roast Formulas the BINLBS field will be deducted by the Green Bean Module or the Roast Module during production to maintain accurate inventory values. If your Single Orgin BINLBS values are not being maintained properly with receipt of new coffee shipments or through the production process there is a configuration issue that needs to be addressed.

In the form below, the ReorderPoint field is an optional field to be used as a reminder when to order new Coffee. For the Columbia Single Origin Below, the current BINLBS value is below the Reorder point and the BINLBS field is displayed with a Red background. A yellow background indicates that you are approaching the ReorderPoint.

The CurrentLot field is a new item in the SingleOrigins form providing a way to automate Roast Log Lot entries during production where all bags of the CurrentLot are roasted before switching to a new Lot. The Roaster needs to enter the Lot in this field that is currently being roasted, when the lot changes at the point in time of the change the CurrentLot value should be changed in this form and the change will be automatically propogated into upcoming Roasts.

The PendingLbs field is also new and applies only to the CoffeeRoaster Scheduling Module. This field represents the LBS total that is needed for items that have been added to the 'Pending' list before they are Scheduled.

For those who have the CoffeeRoaster Management Module the form header will show the estimated value of their Green Bean inventory.

The first time that you configure this form you will want to

enter the BINLBS for the current inventory. These values may change

depending on operator choices when new coffees are added to the Deliveries form.

If you enter your Delivery receipts after configuring the BINLBS make sure that

you select the option to not add the receipts to the BINLBS, otherwise, after

adding the received coffees your BINLBS will change and will need to be reset.

Once you have reconciled your Delivery Receipts and start with an accurate

inventory lbs (BINLBs), CoffeeRoaster will manage the BINLBS and needs to be

checked periodically with a physical inventory to verify that Configuration and

user procedures are accurate.

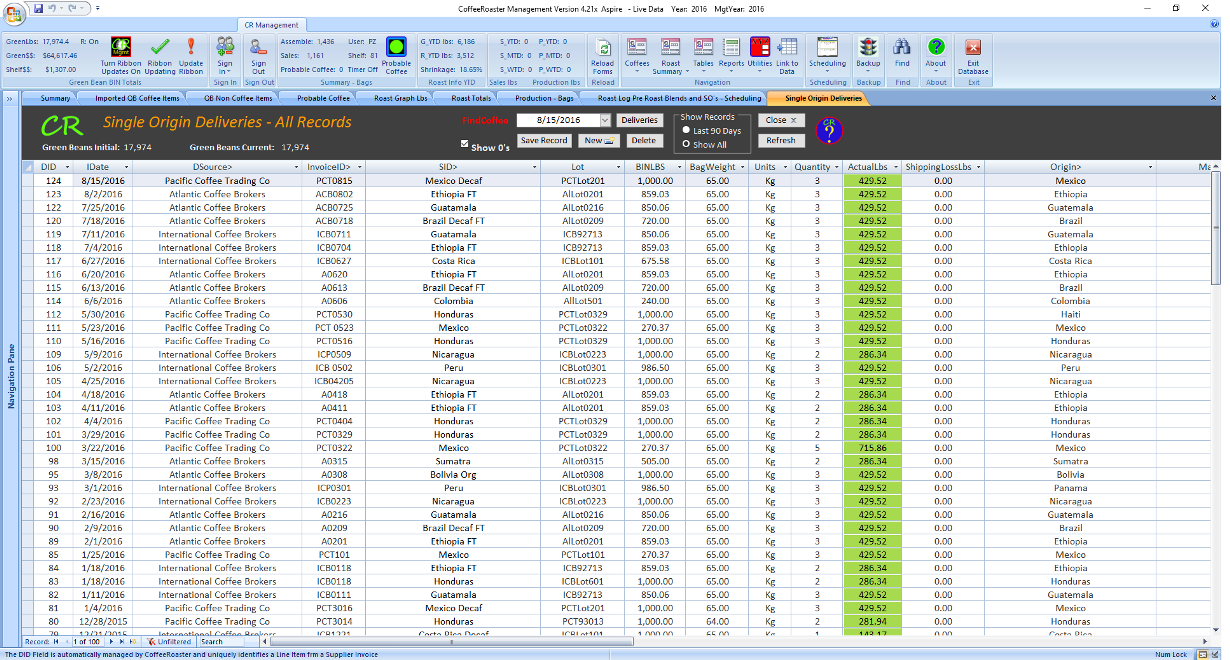

Single Origins Delivery Form

Accurate completion of the Single Origins Delivery form is an important part in creating a record of coffee receipts but also of adding the correct amount of coffee to the proper Single Origin BIN. The important fields are displayed below and should be worked from left to right, some fields will be automated but most will requre a data entry. The fields are:

- DID - an automated field that is a unique number representing that delivery item

- IDate - a date field - this field should match the Invoice Date from the supplier paperwork

- DSource> a pulldown menu that allows you to select a Supplier from the list previously created in a lower order form

- InvoiceID> - the Invoice Number from the Supplier paperwork

- SID> - this field is formed from a pulldown menu displaying the current entries in the Single Origins Form. Select the item that matches an item in the drop down menu for an incoming Single Origin that will be used to replenish an existing Single Origin. For a new Single Origin, enter a new SOName value and a new Single Origin will be created in the Single Origins Form. For a new Single Origin the BINLBS will not be managed by CoffeeRoaster until after Roast Components have been configured and connected to Final Roasts.

- Lot - enter the Lot value from the Supplier paperwork. These entries will be used in pulldown menus of other forms along with the date to make Lot selections.

- BINLBS - this field represents your current inventory of a specific Single Origin. When new coffee is received in this form you will have the option to add to new lbs to the BINLBS field for this Single Origin.

- Bag Weight - the weight of the bag from the supplier paperwork, normally this is in metric units and will be automatically converted to lbs if desired when the BINLBS is adjusted

- Units - select Kg or Lbs, usually Kg is specified by the supplier paperwork and this would be the correct choice

- Quantity - the quantity of bags for that Single Origin from the Supplier paperwork

- ActualLbs - the calculated weight in Lbs of the Quantity times the Bagweight, converted to Lbs

- Shipping Loss - normally 0, if you indicated that you had a damaged bag you will want to create a new row for the damaged bag and the actual Lbs received can be entered. Make sure that you deduct 1 if necessary from the Quantity of the previous row.

- Origin - a pulldown menu that allows you to select a country source

- Marks/Seals - an optional field for additional Coffee bag information

- Notes - optional field for notes on the specific row of the shipment

- Added to BIN - a field that is managed by CoffeeRoaster, this will normally be checked when new shipment lbs are added to the BINLBS value of the appropriate Single Origin

- LastModified - a time stamp for the row managed by CoffeeRoaster

- TimeCreated - a time stamp for the row managed by CoffeeRoasster

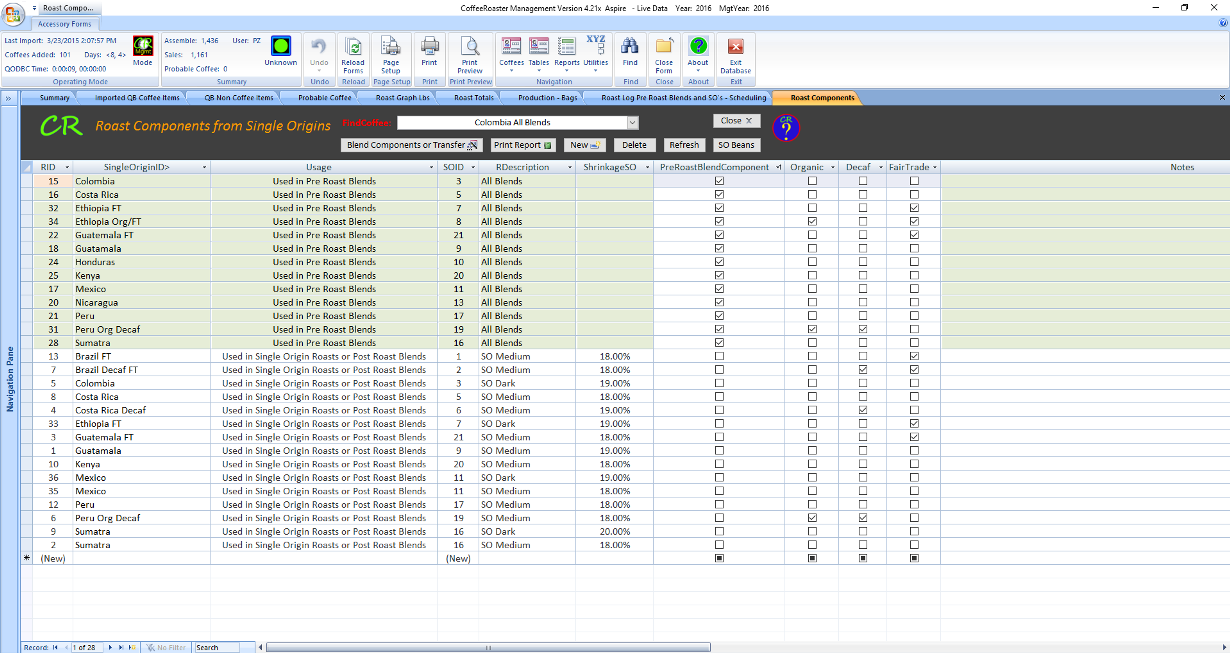

Roast Components Form

The Roast Components form, shown below, is the critical link between Final Roast packaged products and their source Single Origin BINS. The use of Roast Components to connect finished product to Single Origin BINS allows for detailed breakdowns of needs for specific Roast Components, this is a capability that has been requested by some Coffee Roasters. The Roast Component Form, shown below, must be completed before a Final Roast is configured as the Roast formula will be comprised of entries from the Roast Components Form. Correct configuration of Roast Components and their connection to Final Roast products will assure the ability of CoffeeRoaster to accurately maintain Single Origin BINLBS values.

The fields of the Roast Component Form are the following:

- RID - a unique number assigned to the Roast Component, this value is connected to by other Forms using different field names

- SingleOriginID> - a pulldown menu representing the Single Origin that BINLBS deductions will be made from

- Usage - This field will be set by CoffeeRoaster when the PreRoastBlendComponent field is checked or unchecked. There are two types of Roast Components, Single Origins which are mixed with other components and then Roasted together (Used in Prre Roast Blends) and secondly, Single Origins which are roasted individually to a specific Shrinkage (Used in Single Origin Roasts or Post Roast Blends). For components Roasted together as part of a Pre Roast Blend, the shrinkage value is NOT configured in this table but instead is configured as the RoastShrinkage field in the Final Roast form. The shrinkage that these components will experience is determined by what Final Roast (Pre Roast Blend) they are part of. Please notice in the form below that the ShrinkageSO field is left blank for PreRoastBlend components. The converse is true for Single Origins roasted individually to different Shrinkages. These components need to have a Shrinkage configured (ShrinkageSO) that allows you to differentiate between Single Origins roasted at different levels within a Single Origin. In the form below both the Mexico and Sumatra Single Origins have multiple Roast Components configured, each with a different Shrinkage.

- SOID - this value will be determined automatically by the value you select in the SingleOriginID> field.

- RDescription - The RDescription field is a descriptor for how this component will be used and connected to Final Roast Formulas. This is an important entry that will propogate through to other forms, keep this as short and descriptive as possible. For most Roasters, it is best to connect Roast formulas to Single Origin BINS for Pre Roast Blend Components through a Single Roast Component labeled 'All Blends'. This component does not need a ShrinkageSO as the shrinkage value that comes into play could change with different Final Roasts and is specified there as the Roast Shrinkage. For Single Origins that are roasted individually for Packaging or Blending you need to be somewhat descriptive in this field describing in some way the different Roast Levels that are rerpresented for that Single Origin. For example, if the Single Origin 'Mexico' is roasted at 3 different shrinkage values, then this could be SO Light, SO Medium and SO Dark. The end Roast of each of these would have different flavor characteristics from the other and multiple Roast components must be configured. The Roast Description field is often concatonated with the Single Origin Name (SOName) in other forms representing Roast Components, so the Description for a Roast component will often be the combination of the Single Origin Name and the RDescription field. Examples would be 'Colombia All Blends', Mexico SO Medium, Mexico SO Dark.

- ShrinkageSO - the estimated Shrinkage of the Single Origin Roast Component. This is an important estimate for the Green Bean Module as this shrinkage is used by the Green Bean Module to calculate BINLBS deductions based on 'Finished' coffee items. For Roasters with the Roast Module, the BINLBS deduction is a direct deduction and does not need to be estimated. For Roast Components that are part of Pre Roast Blends leave this field blank.

- PreRoastBlendComponent - this field will be checked for components that are Roasted with other Single Origins as part of a Pre Roast Blend and Unchecked for All Single Origin Roasts

- Organic - a simple check box indicating whether the Single Origin as received from the supplier is considered Organic

- Decaf - a simple check box indicating whether the Single Orgin as received from the supplier is considered Decaf

- FairTrade - a simple check box indicating whether the Single Origin as received from the supplier is considered Fair Trade

- Notes - optional field for component notes

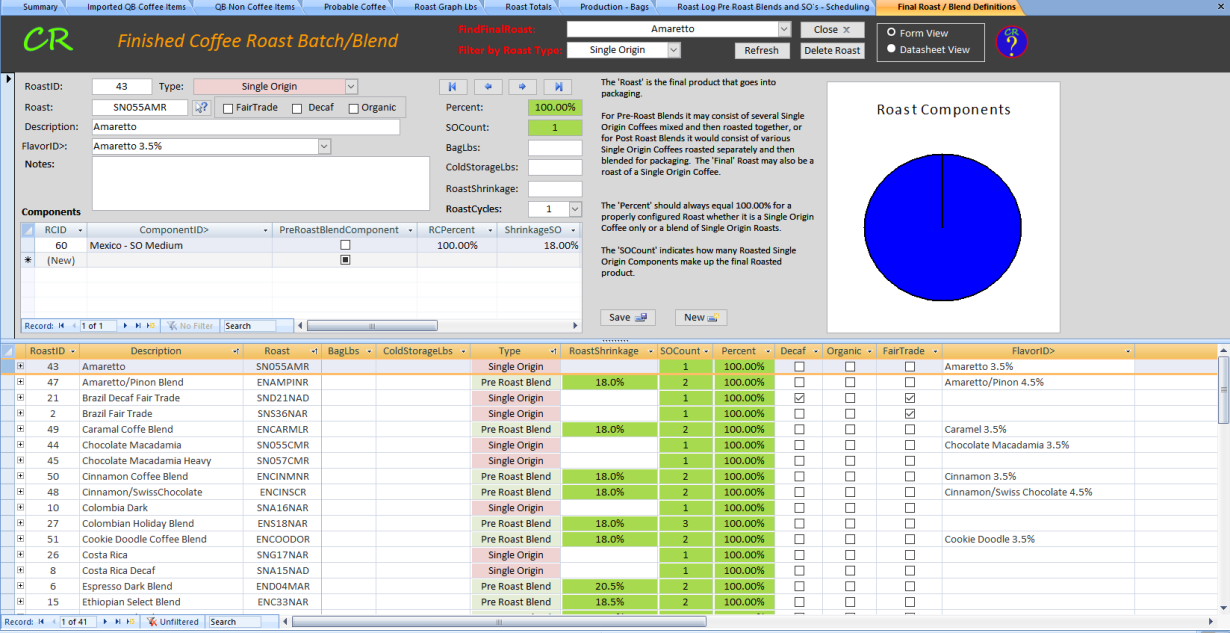

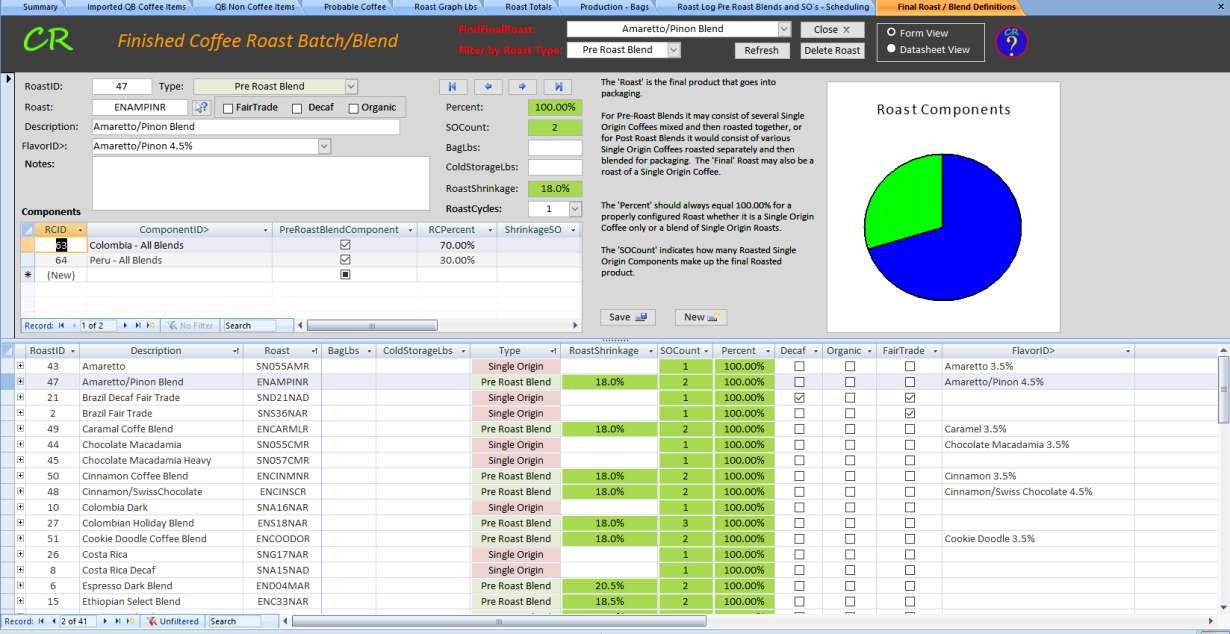

Final Roast Form - a higher order form configured after Single Origins and Roast Components have been configured

The Final Roast form represents a final product ready for bagging, it is composed of Roast Components and through Roast Components is connected to specific Single Origin BINS. There are three general categories of Final Roasts, these are:

- Single Origins - Single Origins roasted to specific Shrinkages and then packaged as Single Origins

- Post Roast Blends - a blend of 2 or more Single Origins roasted to specific shrinkages as Single Origin Roast Components

- Pre Roast Blends - a blend of Single Orgins roasted together and then sent to packaging in that form

In the form below a Pre Roast Blend 'Final Roast' is shown allowing configuration of the Components used to Blend the Roast and also allowing a connection to Flavoring if the Flavoring Module is used. Each 'Final Roast' has a unique numeric ID number, the RoastID. The fields of the Final Roast form are discussed below:

- RoastID - a Unique number identifying this particular Final Roast

- Type - Select from Post Roast Blend, Pre Roast Blend or Single Origin

- Roast - this is a text string used to uniquely identify the Roast, Aspire recommends using specific characters for some of the fields

- Fair Trade - a Final Product Attribute that represents whether the item is considered 'Fair Trade' for Marketing/Certification purposes

- Decaf - a Final Product Attribute that represents whether the item is considered 'Decaf' for Marketing/Certification purposes

- Organic - a Final Product Attribute that represents whether the item is considered 'Organic' for Marketing/Certification purposes

- Description - the common descriptive name used in the business for this item

- FlavorID> a drop down box connected to Flavors (must have the Flavor Module and Flavors preconfigured)

- Notes - Optional Notes - it is recommended that you put the preferred formula for this Final Roast in the notes field so that after Single Origin changes necessitated by availability you can return easily to the preferred formula

- Percent - a calculated field from the RCPercent value in the Subform - this should always total 100%

- SOCount - a calculated field that lists how many Roast Components are configured. For Single Origin Roasts this should always be 1, for Pre Roast or Post Roast Blends it should always be greater than 1

- BagLbs - the current value of Roasted Coffee ready for immediate production - this must be manually maintained during the production process at the end of a production Run. This value can be useful to the Roaster so that the Roaster can be aware of leftover coffee from a previous production run that is available for bagging.

- ColdStorageLbs - the same as the BagLbs value except that this is coffee from longer term storage

- RoastShrinkage - a required field for Pre Roast Blends, should be left blank for Single Origins

- RoastCycles - a value used in the Scheduling Module for Post Roast Blends

- Components Subform - this subform is critical in connecting previously configured Roast Components to Roasts. Begin by selecting the correct ComponentID> from the drop down menu. This value connects the Roast to a specific Roast Component and through that component to a Single Origin BIN. For Pre Roast Blends select from only components that are configured as Pre Roast Blend Components. For Single Origins and Post Roast Blends select from Single Origin Components. Once a component is selected, enter a RCPercent value as shown below. This is a blend of Colombia - All Blends at 70% and Peru - All Blends at 30%. For Single Orign Roasts, the RCPercent will be 100%. The ShrinkageSO field for Roast Components for a Pre Roast Blend roast as shown below should all be empty, as the 'composite' shrinkage for the Roast is determined by the RoastShrinkage field.

- Roast Components Graph - simple pie chart representing the proportions of the individual Roast Components

The form below shows a Single Origin Roast. Notice that

there is only 1 Roast Component, that the Roast Component PreRoastBlendComponent

box is not checked, and that there is a ShrinkageSO value attached to the Roast

component that comes over from the Roast Component Form. The total Percent

is 100%, but that is because the Single Component is configured at 100% for the

RCPercent field.