|

Aspire began working with Hunter Bay Coffee Roasters

in June of 2013 at the request of owner, Rob Young.

Rob was a new owner for the business and was

interested in growth and improving the management of

Coffee production. At the time, Rob requested that

Aspire build a version of CoffeeRoaster with the

ability to connect to QuickBooks Online. This had

not been done before, as CoffeeRoaster was

originally designed to connect to an ODBC database

and began production with QuickBooks in early 2009

on local, desktop versions of QuickBooks. An

agreement was reached between Aspire and Hunter Bay

to do a pilot project with the aim of deploying

CoffeeRoaster successfully.

It took time to re-develop CoffeeRoaster into a

product that would be able to connect to its data

source over the internet, a less reliable connection

than a local Hard Drive or Networked File Share. At

the time this development was finishing up unbeknown

to us, QuickBooks was in the process of obsoleting

the QuickBooks Online product and replacing it with

a newer, improved product. A few months before

QuickBooks replaced their current QuickBooks online

product Aspire was able to successfully connect

CoffeeRoaster to an internet based data source

(QuickBooks Online) and import Sales data for the

purpose of running a Coffee Roasting, Bagging and

Inventory application. At the time, it was

uncertain whether a third party tool used to connect

to QuickBooks data over the internet was going to be

available in the future to connect to the new

QuickBooks Online product and the decision was made

to convert to a local QuickBooks product.

There were many challenges shared by Aspire and

Hunter Bay in moving forward in the deployment of

CoffeeRoaster. There was a need to build a

'business network' as opposed to a 'home network' so

that Windows could provide the necessary

capabilities to run CoffeeRoaster properly. There

was also a need for End User training and we have

learned how to get better at that. The many

challenges along the way were met by teamwork and

working to solve the issues and move forward rather

than getting sidetracked by the challenges. People

learned new ways of doing things that led to better

ways of managing Coffee production. This is the

path of successful businesses. There was also a

company culture in transition and this creates its

own set of challenges for long term employees who

are now asked to adapt to change. Again, the

ability to adapt to change for the purposes of

improving the business is critical to moving forward

both for businesses and employees.

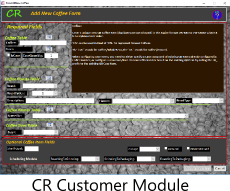

With the CoffeeRoaster software product, it is

critical to maintain properly configured data. With

proper configuration and proper data entry

CoffeeRoaster produces excellent results. If

configuration or data entry are off, the results are

less predictable. Over time, we were able to train

the right individual to manage the configuration

data and maintain data entry, Levi Chagnon.

We are not done yet, we will continue to learn how

to get better - that is the way forward for a

successful businesses. Today, we are beyond the

challenges of deploying CoffeeRoaster and in a

position to reap its benefits. The information

below comes from Levi describing how he sees the

impact of CoffeeRoaster on the Hunter Bay Coffee

Roasting business.

At Hunter Bay Coffee Roasters the following

CoffeeRoaster Modules are deployed.

1) Production Module

2) Management Module

3) Green Bean Module

4) Roaster Module (Pre Roast Blend Model)

Since 2016 there have been changes to the crew at

Hunter Bay with two changes in the Operations

Manager and a change in the Roaster. In

addition, a second location has been added with a

single QuickBooks Company file managing orders for

both locations and both Roasteries. As of

March 2018, Aspire has been involved in a testing

phase to verify the ability for new changes in

CoffeeRoaster to separate imported coffees for

production based on location. Preliminary

testing has been satisfactory, final testing is

expected to occur in April - May 2018.

March 30, 2016

We have been using the CoffeeRoaster program from

Aspire to manage our production materials and order

fulfillment systems over the last three years. I

have been very happy with the programs ability to

make data easily accessible and streamline

operations.

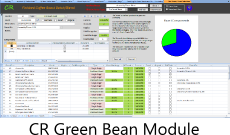

The program does many valuable things for us

including helping us monitoring our production

volumes, managing our blend recipes, record our

incoming coffee deliveries, and managing our order

fulfillment and production needs. We have seen

improvements in:

- Receiving of green coffee

- Managing green coffee inventories

- Tracking lot numbers

- Roasting records

- Blend management

- Order fulfillment

- Roasted coffee packaging

It has taken a dedication to efficiency and

progression in order to make the transition into

using software to manage production and inventories.

As our company has grown, we have seen the necessity

for the CoffeeRoaster program to manage these

things.

Levi Chagnon

Project Manager

406.273.5490

levi@hunterbay.com

|